Then I increased the angle to about 30 degrees to spread the plaster with varying lengths of strokes. Starting from the upper left corner of the side I was working on, I applied a thin coat by holding the knife at about a 15-degree angle. Tip: I recommend experimenting and practicing with the following technique on a scrap piece of drywall before applying it to your hood.įirst I applied a base coat.

Since I wasn’t working with a large area, I opted for a large joint knife versus a trowel. Once it dries, it will be the color you ordered. Wet plaster is much darker than its final color. I loaded up my hawk with plaster and went to work. Using a smooth roller, I applied an even coat of the primer, which is very thick and grainy. But it was necessary to achieve the look we wanted. To be honest, the drywall guys did such a great job, I felt bad applying plaster on top of it. When applying plaster to drywall you have to use a special primer to help the plaster stick to the surface.īefore I applied the primer, I taped all of the edges around the hood and covered the range and countertops with plastic. I ordered 1 gallon of Marmorino Piatto and 1 quart of Anchor Primer. I chose the same color as our walls: Sherwin Williams Pure White. You can get it tinted with almost any paint color. I finally decided on a product called Marmarino Piatto from Firmolux. I did a lot of research on what type of plaster to use for the hood. This way I would have a nice and smooth foundation for the Venetian plaster. Since I don’t do drywall or have a desire to ever do it, I had the drywall crew go ahead and wrap the hood framing and finish it. I won’t go into detail here since each one is different. You can refer to the installation instructions that come with your vent hood insert. But any insert of your choice should work.

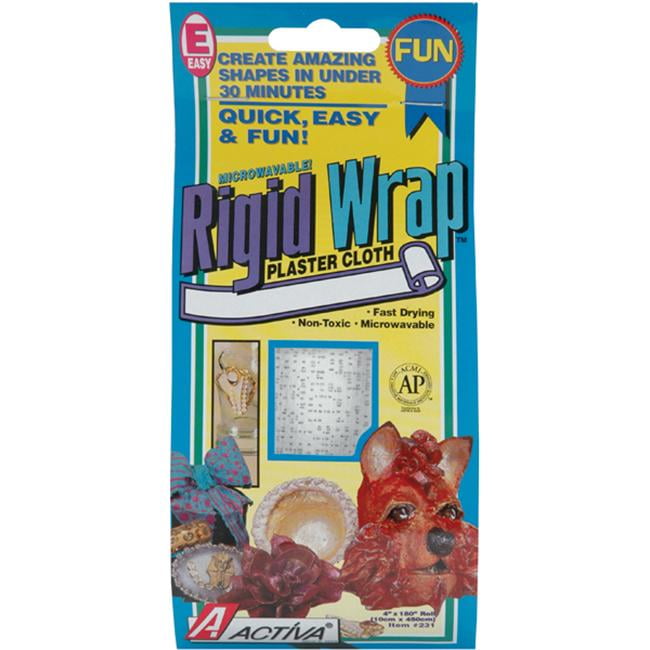

RIDGID WRAP PLASTER CLOTH INSTALL

Step 3: Install the Vent Hood InsertĪs mentioned above, we chose the 46″x21″ hood insert from ZLINE which was very easy to install. Once I had completed the above steps, I felt like the framing was sturdy, but for good measure, I added a few more pieces to beef it up. I spaced seven pieces of 1×4 evenly across the front of the hood and nailed and glued them in place. Since 1x pine doesn’t bend very well, I decided to use MDF for the front pieces that created the swoop. The vertical placement and length of these pieces will determine the amount of swoop on the front side of the hood.

I connected the two with a piece across the front as shown in the illustration above. I then added a horizontal piece to each side with the front ends cut at a 12-degree angle. I nailed and glued these into place as shown in the illustration above. Next, I added vertical pieces of 1×4 to the sides to connect the top and bottom. I added screws later to the framing where needed for added strength. I glued and nailed them in place with a finish nailer. I used 1×6 pieces of pine for the bottom and 1×4 pine for the top. I started with the bottom and top frames. Since I was working alone and didn’t have anyone to help me lift it into place, I decided to frame it in place. Or you can frame it in place on the wall. You can put it all together and then mount it to the wall and ceiling. There are two approaches you can take when framing your hood. Our ceiling height is 10′ and the recommended hood height is between 30″ and 36″. The height of the hood is determined by the height of your ceiling and the recommended distance from the bottom of the hood to the top of the range. So the width of our hood framing ended up being 51 1/2″, and the depth was 23″.

RIDGID WRAP PLASTER CLOTH FULL

We knew we wanted a full height quartz backsplash and wanted it to be the same width as the finished hood, and wanted it to be a few inches wider than our range. We chose a 46″x21″ hood insert from ZLINE.Īnother determining factor is the type of backsplash you will be doing. We went with a 48″ ZLINE gas range, which meant we would need a hood insert to accommodate that size of the range. The most obvious deciding factor is the size of your range. The first thing I did was to determine the size of my hood.

RIDGID WRAP PLASTER CLOTH HOW TO

Ready to learn how to build a plaster hood? Let’s get started! Step 1: Determine the Size of Your Plaster Range Hood

0 kommentar(er)

0 kommentar(er)